AIR FILTRATION BASICS

Clean air is becoming more and more important in today’s world. People are concerned with cleaning outside air and reducing pollution, cleaning inside air for the health and comfort of individuals inside buildings, and finding energy-efficient ways to clean air. Having a basic understanding of air filters and how they work can make the daunting task of purchasing a new air filter a little easier.

WHAT IS AN AIR FILTER?

An air filter is a device that cleans air. It removes contaminants such as dust, mold, and bacteria from the air. (See How air is filtered)

Air filters are constructed of filter media, sealants, a frame, and sometimes a face guard and/or gasket.

- Media is the filtering material. Common types of media include glass fiber, synthetic fiber, non-woven fiber, and PTFE.

- Sealant is the adhesive material that creates a leak-proof seal between the filter media and the frame.

- Frame is where the filter media is inserted. It can be made from a variety of materials, including aluminum, stainless steel, plastic or wood.

- Face guard is a screen attached to the filter to protect the filter media during handling and installation.

- Gasket is a rubber or sponge-like material used to prevent air leaks between the filter and its housing by compressing the two together.

Air enters the filter through the upstream side. It flows through the filter, contaminants are taken out of the air, and the clean air exits through the downstream side. How clean the air is on the downstream side depends on the efficiency of the filter.

Efficiency is the filter’s ability to remove particles from the air. Different applications require different levels of efficiency.

HOW IS AIR FILTERED?

There are three types of air filters: mechanical, electrostatically charged filter media, and electronic air cleaners. Mechanical filters remove dust and particles by capturing them on the filter media. Electrostatically charged filter media, in which the fibers of the media are charged, increase filter efficiency. Electronic air cleaners attract charged particles to oppositely charged collectors.

Cambridge Filter USA manufactures mechanical filters. There are three different ways mechanical filters work.

Straining Effect

Straining occurs when the particle is bigger than the space between the fibers of the filter media. The particles then collect on the filter media. Straining is only effective with larger particles, such as hair or lint.

Interception

In this method, particles are small enough to follow the air stream. The particles come in contact with the fibers and remain “stuck” to the fibers because of a weak molecular connection known as Van der Waals’ Forces.

Diffusion

Diffusion works with very small particles and works in HEPA and ULPA filters. The particles are so small that they move in a random motion within the air stream. The random motion causes the particles to stick to the media fibers.

Why use air filters?

The simple answer to this question is to clean the air. Here are some examples where air filters are used:

- Cars

- Gas Turbines

- Semiconductor Fabs

- Air Conditioning Units

- Office Buildings

- Airplanes

- Vacuum Cleaners

- Research Labs

- Hospitals

- Food Processing

- Nuclear Facilities

Air Filters in Use

- Public Buildings

- Outside air is brought into the building, filtered, and circulated throughout the building. Smog, dust, pollen and other particles are filtered out to create a comfortable and healthy environment for people inside. As public awareness increases, Indoor Air Quality (IAQ) is becoming more important. Poor IAQ can lead to sick building syndrome (symptoms include headaches, eye irritation, and fatigue), which can lead to discomfort and low productivity.

- Government buildings are using more efficient filters not only to improve IAQ but also to help protect people from the threat of bioterrorism, such as anthrax.

- Medical Facilities

- Hospitals and clinics use high-efficiency filters to prevent the spread of infectious diseases. Clean air is especially important in operating rooms, intensive care units, and other critical-care areas. Enzymic filters are also used because of their ability to capture bacteria and actually destroy it.

- Food Industry

- Facilities require clean air to prevent contamination and to ensure the food being processed and packaged is safe for consumers.

- Critical Manufacturing

- Industries such as pharmaceutical, microelectronics, and research laboratories require super-clean air for their manufacturing processes. One use for high-efficiency filters is in pharmaceutical and research laboratories to prevent cross-contamination. Other industries requiring highly filtered air are semiconductor, LCD manufacturing, microelectronics, and nanotechnology. Particles smaller than a single piece of dust can ruin an entire process in these industries, so clean air is critical. Industries requiring this level of cleanliness do their manufacturing in cleanrooms.

WHAT IS A CLEAN ROOM?

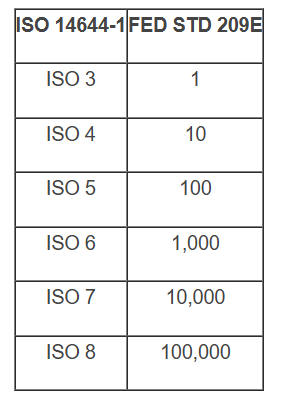

Cleanrooms have a controlled level of contaminants specified by the number of particles per cubic meter and by the maximum particle size. They are classified by their level of cleanliness. The following tables show the different cleanroom classifications (US FED STD 209E cleanroom standards):

Common Particles and Their Sizes

Human Hair: 70–100 μm

Human Sneeze: 10–100 μm

Pollen: 5–100 μm

Spores: 6–100 μm

Mold: 2–20 μm

Smoke: 0.01–1 μm

Bacteria: 0.35–10 μm

CHOOSING THE RIGHT FILTER

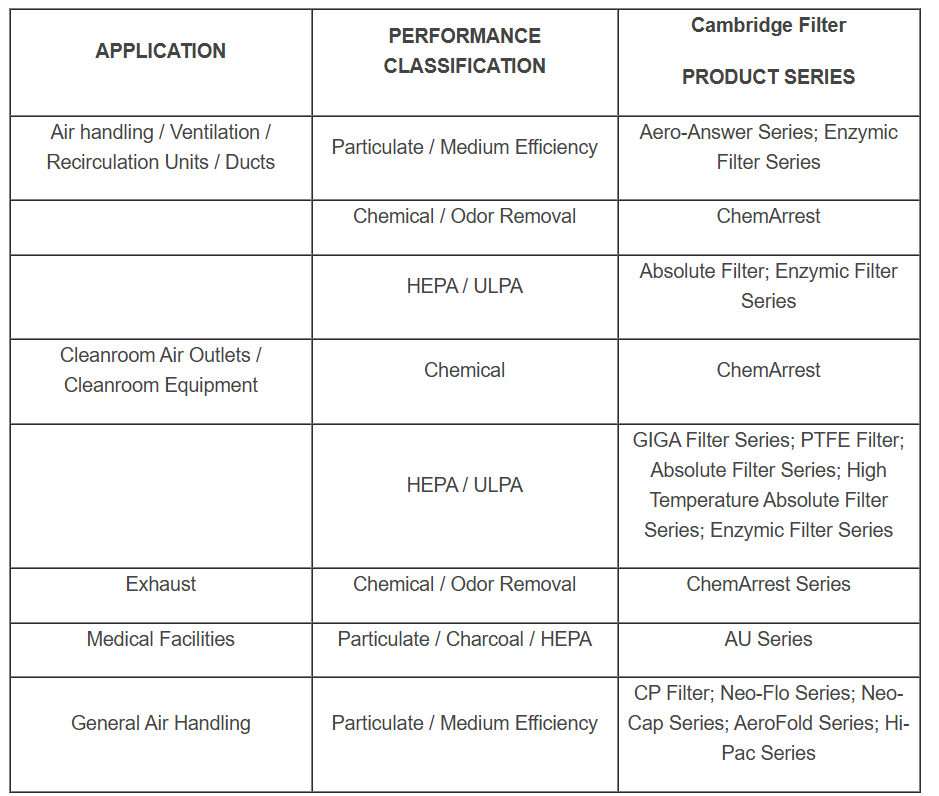

First, you need to ask yourself, “What am I trying to filter?” Are you trying to filter dust? Odors? Sea salt? Chemicals? Etc.? Next, you need to know the filter’s application. Will it be used for recirculation units? Cleanrooms? Medical facilities? Tools? What level efficiency you require?

Answers to these questions will vary, as will the type of filter you should use. Below are our recommended uses for filters based on specific applications.

If you are still uncertain about what filter you should be using in a particular application, contact one of our sales representatives.

Filters are used to clean air in a variety of applications. They work to protect people in public buildings, patients in hospitals, and critical manufacturing processes. Filters are carefully engineered and designed to operate at specified efficiencies. Higher filter efficiency means that the filter is retaining smaller particles. It is important to know why a filter is being used and what requirements need to be met (e.g., efficiency, airflow, pressure drop, and dimensions) to optimize the filter’s performance. Cambridge Filter USA is committed to quality and service. Let us help you with your filtration needs.

© 2023 All Rights Reserved | Cambridge Filter USA